Consultancy, design, innovation and manufacture of mining, mineral processing and recycling equipment

Capacities & Technical Specifations

Cone Crushers

CC & CC-S SERIES CONE CRUSHER

Brief Introduction

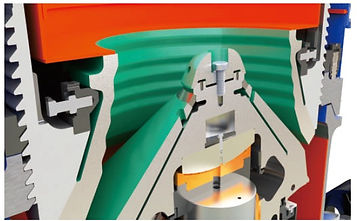

MP CC and CC-S Cone Crusher applies material selection crushing technology (MSCT). The crushing chamber is designed to accept a constant feed of suitable material for all round crushing and self-breaking, which helps to reduce excessive wear of the liners.

The MP Cone Crusher is advanced in design, more compact with a higher crushing ability and efficiency to provide better size reduction. Operators can choose the auto control mode, various chambers and other features by adjusting the closed side settings (CSS). All models are easy to operate and maintain, with high production and efficiency.

MP Cone Crushers have a wide utilization for crushing. The Cone Crushers can easily meet different production needs by selecting crushing chambers and different eccentricities. The MP Cone Crusher is an excellent choice as secondary or tertiary crushing equipment and the compact structure makes it easier for maintenance and also ideal for portable crushing plants.

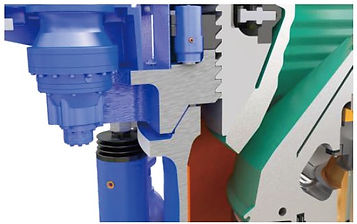

The hydraulic adjustment system provides safety protection and adjustment of the discharge port settings. The hydraulic adjustment system provides automatic overload protection to allow non-breakable materials to pass through and automatically return the main shaft to the correct position. The hydraulic control system can monitor the crushing load inside the crusher, recording production data and performance automatically, offers the operation curve and improves the information recording capability. Determining the liner wear by making the calibration and reminds users to replace the liners, so as not to damage the machine.

CC & CC-S Series Cone Crusher Features

-

Higher capacity with higher crushing efficiency.

-

CLP constant crushing chamber remains the maximum feed size with higher production.

-

Progressive crushing creates product in better size to suit requirements.

-

Multiple choices to the chambers on each model.

-

Automatic control and optimized crusher settings by monitoring and recording the load inside.

-

Automatic overload protection offered by hydraulic adjustment system by resetting the main shaft position.

-

Easy operation and maintenance. The inspection and maintenance can be accessed from the upper crusher.

-

Higher capacity with a more compact motor, better energy-savings.

The internal working of the Cone Crusher

Specification

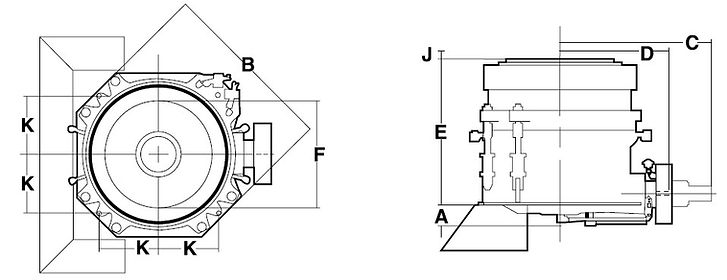

Dimensions are intended only as a guide for preliminary planning of the installation and should not be

used for the construction of foundations etc.

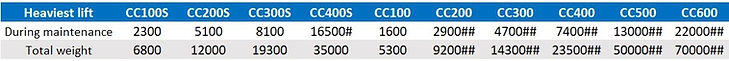

Approximate Weights - Unit: KG

# 16500 kg = top shell assembly + spider assembly.

9700 kg = top shell assembly only.

## Applies to crusher with fine crushing chamber. With coarse crushing chamber these weights are reduced by approximately 380kg for the CC200, by 600kg for the CC300, by 600kg for the CC400, by 600kg for the CC500 and by 3800kg for the CC600 model.

CC-S crushers

Three standard crushing chambers are available.

MC = Medium course

C = Course

EC = Extra course

CC crushers

Several standard crushing chambers are available.

EEF = Extra Extra Fine EF = Extra Fine

EFX = Extra Fine Extra F = Fine MF = Medium Fine

M = Medium MC = Medium course

C = Course CX = Course Extra EC = Extra course

Capacity(TPH), the above specification is an estimated performance of crusher.

The data in the table is for the performance of the crusher feed with the dry material with a specific gravity of 1600kg/m3 in an opened circuit operation, also assumed the feed material's maximum size is under crusher's maximum feed size and does not contains finer material less than CSS.

Since the selected eccentricity, crushing ratio, material crushing work index (Wi), feed particle size composition, circulating load, and moisture in the feed will affect the crusher's ability, so please contact us for further information.

MHP SERIES CONE CRUSHER

.jpg)

.jpg)

Brief Introduction

MHP series Cone Crushers are compact units and used in a wide range of applications. Well suited with its unique combination of speed, throw and cavity design providing maximum production with superior performance, consistent gradation and quality products for medium to hard material for secondary, tertiary and quaternary installations. MHP series has a threaded rotating bowl which maintains a consistent, accurate easily adjusted setting by hydraulic motor and with the use of the tramp release system incorporating dual acting cylinders equally positioned around the Crusher, this provides a quick release and re-setting system in the event of foreign objects entering the crushing chamber. This system incorporating a large stroke is also useful for assisting the clearing of stalled crushers, reducing downtime.

MHP Cone Crusher Features

High performance non contact labyrinth seals are wear free and increase reliability of a dust free environment. The compact design ensures fewer moving components come in contact with rocks and dust. All components of the crusher have wear protection, including the mainframe seat liners and pin bushings, replaceable head ball, mainframe base gasket, drive bushing protection plate, counterweight guard plate, mainframe liner and feed hopper which minimise maintenance costs.

The MHP series cone crusher has a two-way hydraulic cylinder system that assists tramp metal to pass through the crushing chamber, while many other crushers may shut down and stall. The hydraulic movement has a large stroke for clearing the crushing chamber independent of the liners, which enables the operators to clear the chamber quickly, reducing downtime and an easier operation of the Crusher.

The hydraulic setting adjustment motor can be used under load to optimise crusher productivity and help to balance the crushing circuit providing better efficiency. Adding a hydraulic motor transducer system to monitor and convert pressures to electrical outputs can be installed to a distributed control system plant to track and control the Crusher automatically

Easier Maintenance

MHP series are fitted with oil pressure lubricated bronze bushings throughout providing extreme load and shock capabilities. Bronze bushes are more affordable and can be easily replaced on site with general tools. All parts of the MHP series Cone Crusher can be disassembled and maintained from the top or side. The mantle and concave are also easy to disassemble and replace.

Concave and Mantle Liners Assembly

Variable Application

MHP series chamber can be easily changed from standard extra coarse to short head extra fine by replacing the concave liner, mantle liner, adapter ring, and wedge lock bolt only.

Easier Adjustment

The hydraulic setting adjustment motor can be used under load to optimize crusher productivity and help to balance the crushing circuit providing better efficiency. Adding a hydraulic motor transducer system to monitor and convert pressures to electrical outputs can be installed to a distributed control system to track and control the Crusher automatically.

Tramp release and Hydraulic settings

Easier Operation

MHP series is fitted with a forged high tensile main shaft and cast steel eccentric, driven by a molly cast steel case hardened carbonized bevel wheel pinions. The small beveled pinion is fitted to a forged high tensile steel counter-shaft and driven by a cast iron vee rope drive pulley.

Counter-shaft Assembly

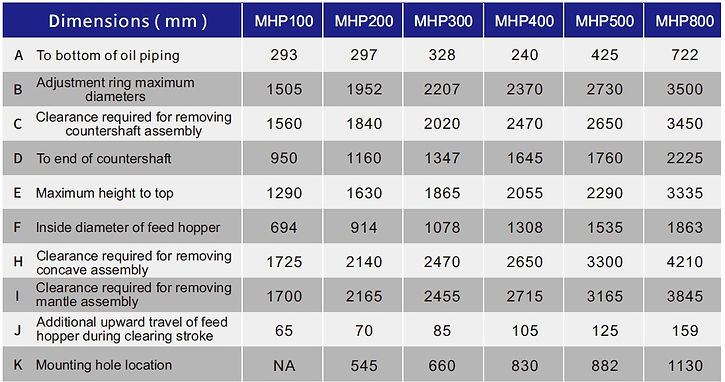

Specifications

Dimensions

Weights (Complete Crusher and Assemblies)

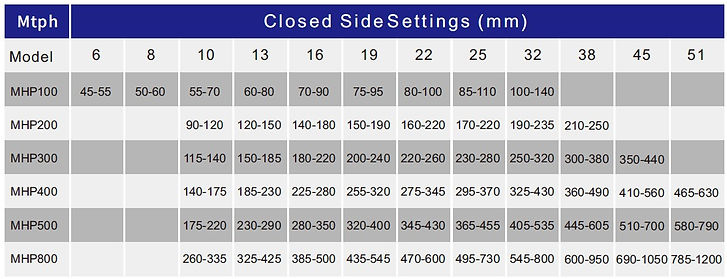

Crusher capacity (TPH)

* Represents capacity through crusher based "instantaneous" product sample

Crusher capacity factors

Cone crusher capacity charts are developed for use as an application tool to properly utilize the MHP crusher's capabilities. The capacity figures shown apply to material weighing 100 pounds per cubic foot or 1600 kg per cubic meter. The crusher is one component of the circuit. As such, its performance is in part dependent on the proper selection and operation of feeders, conveyors, screens, supporting structure, electric motors, drive component and surge bins. Where used, attention to the following factors will enhance crusher capacity and performance.

-

Proper selection of crushing chamber for material to be crushed.

-

A feed grading containing a proper distribution of the particle size.

-

Controlled feed rate.

-

Proper feed distribution 360° around the crushing chamber.

-

Discharge conveyor sized to carry maximum crushed capacity.

-

Properly sized scalping and closed circuit screens.

-

Automation controls.

-

Adequate crusher discharge area.

The following factors will detract from crusher capacity and performance.

-

Sticky material in crusher feed.

-

Fines in crusher feed (smaller than crusher setting)

-

Excessive feed moisture.

-

Feed segregation in the crusher cavity.

-

Improper feed distribution around the circumference of crusher cavity.

-

Lack of feed control.

-

Inefficient use of recommended connected horsepower.

-

Insufficient conveyor capacity.

-

Insufficient scalper and closed-circuit screen capacities.

-

Insufficient crusher discharge area.

-

Extremely hard or tough material.

-

Operation of crusher at less than recommended full load counter-shaft speed.

For individual conditions please get in touch with us.

Gradation Curves

Main Components

Section View

Crusher Cavity Selection

Product Gradation Table (% passing through square mesh depending on the setting)