Consultancy, design, innovation and manufacture of mining, mineral processing and recycling equipment

Capacities & Technical Specifations

Hypro-Screen® Extra Heavy Duty Trommels

Processing gold ore for heap leach plant - Mongolia

Separation and product sizing for diamond, gold, nickel or iron ore, coal, slag, quarry aggregates, sea defence, rip-rap, demolition, waste material, recycling and other minerals.

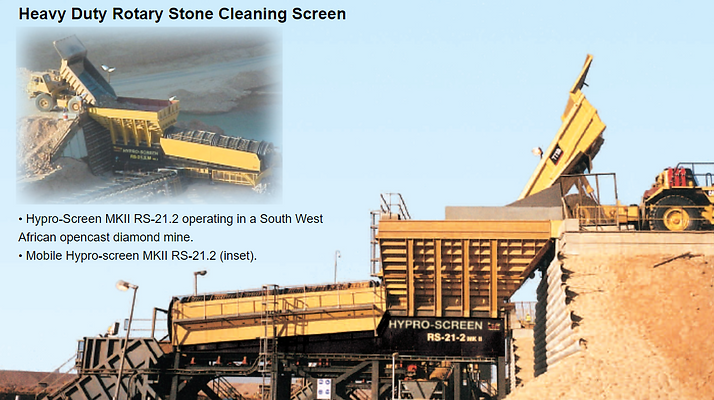

RS212 Tri axle Heavy Duty Mobile Trommel Screen operating at an open cut diamond mine in South Africa, powered by Cat 3116TA Engine Hydraulic Drive reciprocating feeder & 1400TPH Trommel Screen. 200 Ton capacity material Feed Hopper designed to accept 100 Ton Dump Trucks.

RS213 - 1400 TPH Heavy Duty Trommel screen in Namdeb Diamond Mine, Namibia

RS182 - 900 TPH Heavy Duty Trommel screen in Killybegs Harbour Project, Ireland

Quality fabrication, precision machined to ensure accurate assembly

Complete assembly of the Trommel Roller & Feeder Support Base frame

Main Frame - Fabrication Machining

Base Frame & Main Support structure for Rollers, Trommel, Feeder & material Feed Hopper

Trommel screen fabrication and CNC machined to guarantee concentricity on assembly

Trommel screen complete assembly

55 Ton complete Trommel Screen assembly installation

World class fabrication, CNC machining guarantees alignment of complete assembly and accurate roller path placement

Trommel Screen with guarding & double row cleaners fitted

CAPACITIES RANGING UP TO 3000 TONNES PER HOUR

ALL MODELS AVAILABLE AS FIXED, SKID-MOUNTED OR MOBILE

Models and Specification

The Heavy Duty Trommel Screen unit is equipped with many genuine Caterpillar® parts. Service for these components is available from Caterpillar® dealers worldwide.

Capacities of standard models only

Machine total weights

-

Handles one cubic metre down

-

Blasted, ripped or as dug material

-

Contaminated, dry, wet or dirty material

-

Site demolition and waste material

-

Excellent for producing rip-rap

-

Sea defence and pitching stone

-

Pre-screening crusher feed

-

Opencast coal, ore and gravel

-

No permanent operator required

-

No grease points, low maintenance

-

No pegging problems

-

No mechanical vibrators

-

Low power consumption

-

Low speed, quiet running

-

Variable speed reciprocating feeder

-

Diesel / electric, hydraulic drive

-

Capacities and tonnes per hour are approximate and will vary depending on the grade and nature of the material.

-

Note: the output figures are based on a complete plant incorporating an m.w. reciprocating feeder.

-

It is not recommended to constantly feed maximum size lump stone.